The Role of Extension Springs in the Electronic Industry

The Role of Extension Springs in the Electronic Industry

In the electronic industry, even the smallest component plays an important role in product performance. Extension springs, also known as tension springs, are one of these critical components. They help electronic devices operate smoothly, safely, and reliably.

At SS Long Springs Sdn Bhd, we manufacture high-quality extension springs specially designed for electronic applications where precision, consistency, and reliability are essential.

How Extension Springs Function in Electronic Devices

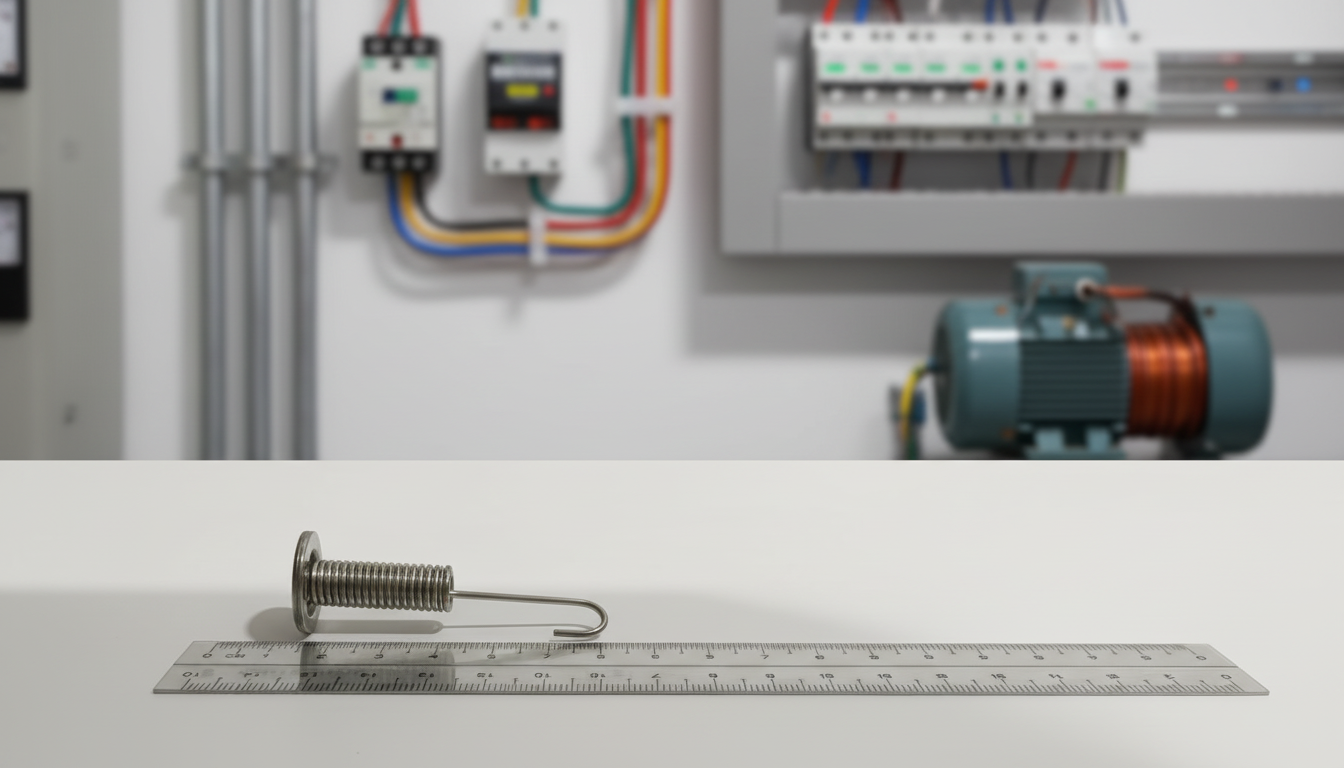

Extension springs work by storing energy when stretched and pulling components back to their original position when released. In electronic devices, this controlled pulling force helps ensure proper movement, contact, and alignment of parts.

Because electronic components are often small and delicate, extension springs must provide accurate and stable force without damaging nearby parts. This makes precision manufacturing extremely important in electronics.

Common Applications of Extension Springs in Electronics

Extension springs are widely used in many electronic products and systems, including:

-

Connectors – to maintain stable contact and positioning

-

Switches – to ensure smooth opening and closing actions

-

Control Panels – to support mechanical movement and return functions

-

PCB Assemblies – for alignment, tension control, and component support

-

Electronic Enclosures – to assist covers, locks, and access mechanisms

These applications require springs that are compact, durable, and able to perform consistently over long periods.

Materials Used for Electronic Extension Springs

Choosing the right material is very important for electronic applications. At SS Long Springs Sdn Bhd, we commonly use:

-

Stainless Steel (SS304 / SS316) – corrosion-resistant and suitable for humid or sensitive environments

-

High Carbon Steel (Music Wire) – high strength and excellent performance for precision applications

-

Oil-Tempered Wire – good fatigue resistance for repeated use

The correct material ensures longer service life and stable performance in electronic devices.

Extension Spring End Types for Electronics

Extension springs can be produced with various end types to suit different electronic designs, such as:

-

Machine hooks

-

Crossover hooks

-

Side loops

-

Custom-designed ends

Proper end design helps ensure secure installation and reliable operation in compact electronic assemblies.

Importance of Precision, Consistency, and Reliability

In electronics manufacturing, precision is critical. Even a small variation in spring force or size can affect product performance.

-

Precision ensures accurate tension and perfect fit

-

Consistency ensures every spring performs the same in mass production

-

Reliability ensures long service life with repeated cycles

High-quality extension springs help reduce product failure, maintenance costs, and warranty risks.

Quality Control and Testing

To meet electronic industry requirements, SS Long Springs Sdn Bhd applies strict quality control and inspection processes, including:

-

Dimensional and force testing

-

Load and tension verification

-

Visual inspection for defects

-

Consistency checks for mass production

This ensures every extension spring meets customer specifications and industry standards.

Custom Extension Springs for Electronic Applications

Electronic products often require custom-made springs. We support customers with:

-

Custom spring design based on drawings or samples

-

Tight tolerance manufacturing

-

Support for OEM and mass production orders

Our team works closely with electronics manufacturers to deliver reliable and cost-effective spring solutions.

Your Trusted Extension Springs Manufacturer

As a trusted extension springs manufacturer, SS Long Springs Sdn Bhd supports the electronic industry with precision manufacturing, quality assurance, and long-term supply capability. We are committed to helping our customers achieve stable and reliable electronic products.

Frequently Asked Questions (FAQ)

1. What is an extension spring used for in electronic devices?

Extension springs provide controlled pulling force to support movement, alignment, and contact in electronic components.

2. Are extension springs suitable for small electronic parts?

Yes, extension springs can be manufactured in miniature sizes with precise force control.

3. What materials are suitable for electronic extension springs?

Stainless steel and high-carbon steel are commonly used due to strength, durability, and corrosion resistance.

4. Why are spring end types important in electronics?

Correct end types ensure secure fitting and stable performance in compact electronic designs.

5. Can extension springs be customized for electronic products?

Yes, custom designs are available based on drawings, samples, or specific application needs.

6. How do quality springs improve electronic product reliability?

Quality springs ensure consistent operation, reduce failure rates, and extend product lifespan.